DPALEX Tarp Manufacturing

DPALEX Woven Tarp Manufacturing Process

As natural disasters become more frequent and intense, reliable emergency materials are no longer optional - they’re essential. At DPALEX, we specialize in mission-ready PE woven tarp kits for temporary roof coverage and other critical response needs. Unlike generic suppliers who treat tarps as interchangeable commodities, we bring engineering precision and operational discipline to every square inch. Here’s how - DPALEX 8-Step Tarp Process.

1. Raw Material Selection & Preparation

What happens: High-density polyethylene (HDPE) resin pellets form the base of all woven tarp production. Most vendors use a blend of virgin and recycled resins, which may be mixed with additives such as UV inhibitors, flame retardants, and color masterbatches.

DPALEX advantage: We use 100% virgin PE resin for optimal strength, weather resistance, and durability. Additives are pre-formulated at precise ratios to meet or exceed FEMA and NFPA UV and flame resistance standards. Our material selection reflects a zero-compromise approach to field reliability.

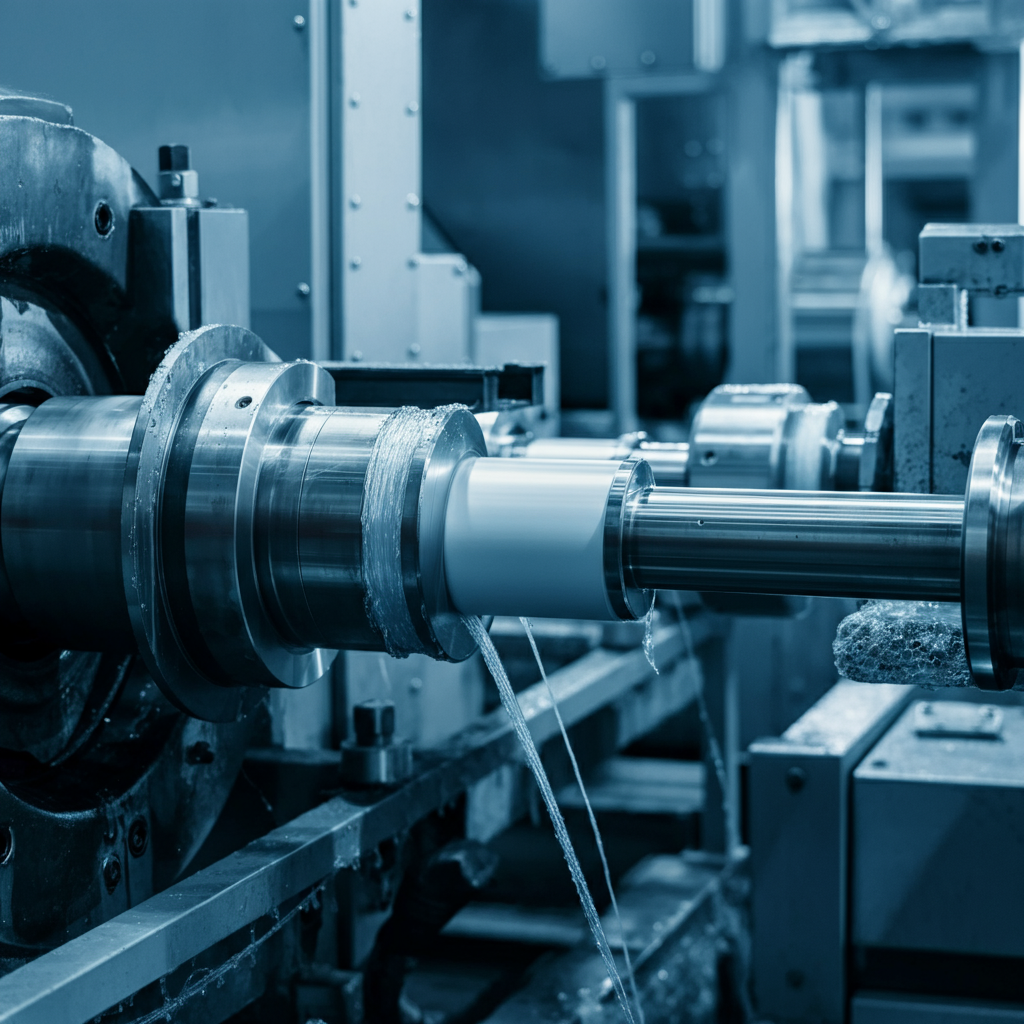

2. Extrusion & Yarn Formation

What happens: Polyethylene resin is heated to precise temperatures until molten, then extruded through flat dies into thin films. These films are slit into tapes and stretched to align the polymer chains—dramatically increasing tensile strength while reducing thickness. The resulting high-strength tapes are cooled, stabilized, and wound onto spools for weaving.

DPALEX advantage: We insist on denier control throughout extrusion and drawing to ensure consistent tape thickness and strength. Our partners use precision dies and high-spec machines to produce yarns engineered for real-world load demands. This eliminates weak points common in commodity-grade products and ensures superior tear resistance, durability, and reliability under tension.

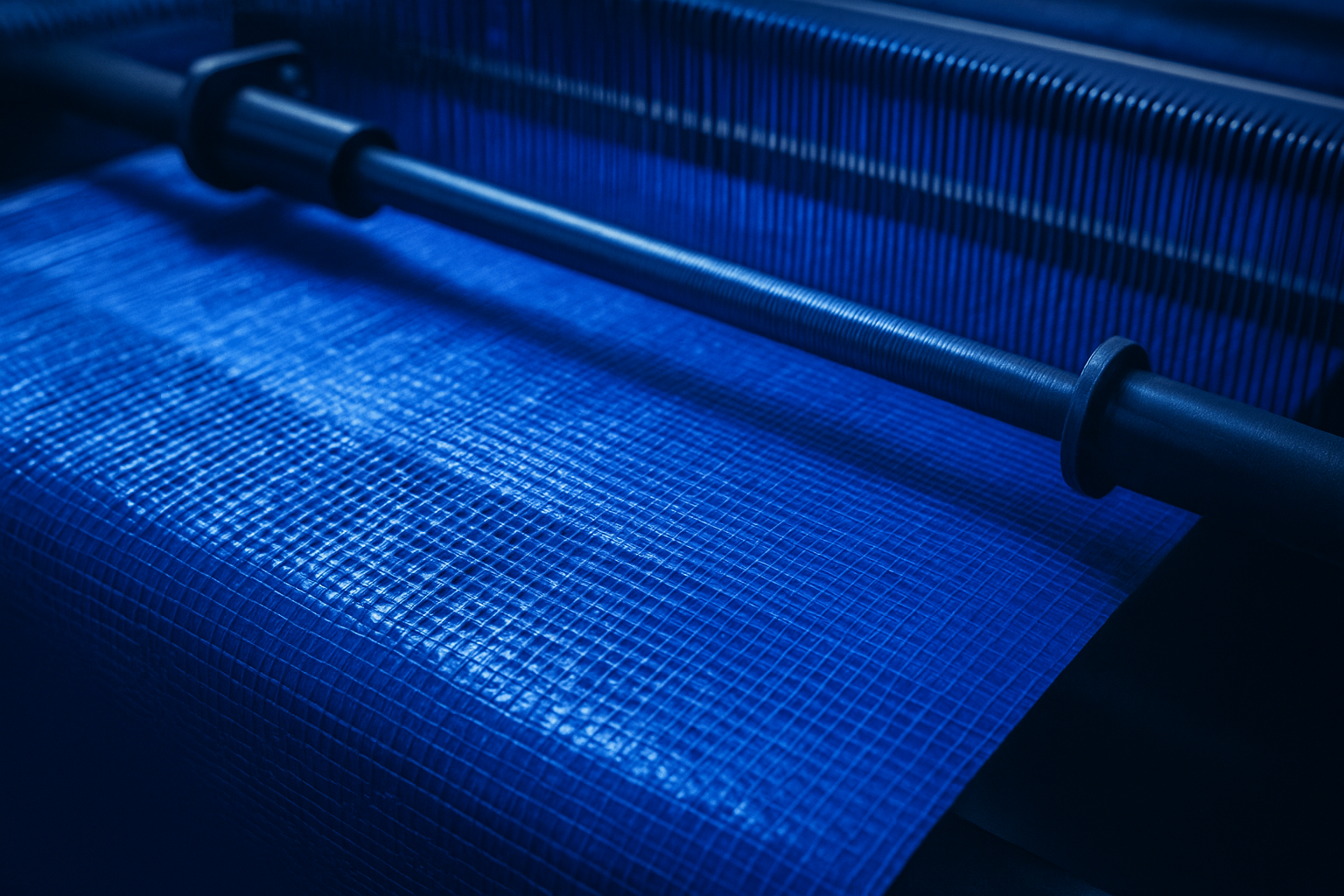

3. Weaving the Mesh

What happens: High-speed water jet or circular looms weave the warp (lengthwise) and weft (crosswise) tapes into a tight mesh - typically 8x8 or 10x10 threads per square inch for commercial and professional grade tarps - which defines the fabric’s structure. Mesh density directly impacts tear resistance, breathability, and final product weight.

DPALEX advantage: We actively partner with precision weaving manufacturers and specify close tolerances throughout the fabrication process. Our mesh is engineered for demanding situations while remaining light enough for rapid deployment and easy handling in the field during an emergency.

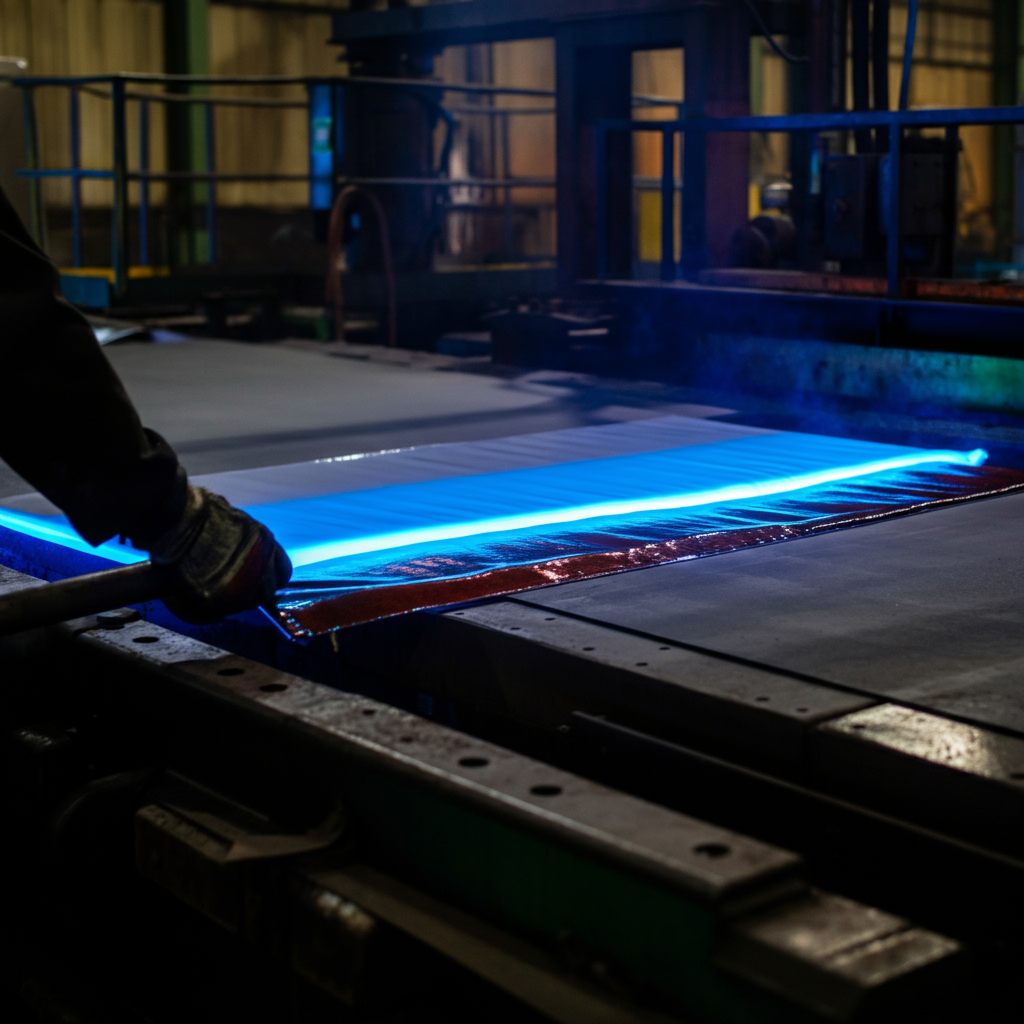

4. Coating & Lamination

What happens: A thin layer of HDPE is extrusion-laminated onto both sides of the woven mesh creating a waterproof surface that also embeds UV and flame-retardant additives. This step enhances durability, prevents fraying, and defines much of the tarp’s real-world performance.

DPALEX advantage: We specify multiple high-density polyethylene coatings with precisely controlled thickness and engineered adhesion strength. This ensures uniform coverage and long-lasting resistance to wind, UV, and rooftop abrasion in the harshest post-disaster environments. Our tarps are independently certified to meet ASTM E84, and ASTM D7238 standards. Commodity-grade vendors often minimize or skip this step entirely sacrificing service life, durability, and safety to cut costs.

5. Heat Treatment & Stabilization

What happens: After lamination, the coated fabric passes through a controlled heat treatment process to permanently bond the layers. This stabilizes the material, relieves internal stress, and activates UV stabilizers to ensure long-term performance in extreme conditions.

DPALEX advantage: Our thermal stabilization process creates a fully bonded material with enhanced tear resistance, dimensional stability, and cold-weather flexibility. Unlike cheaper tarps that may warp, delaminate, or crack over time, DPALEX tarps remain pliable and reliable, even in freezing temperatures and high UV environments.

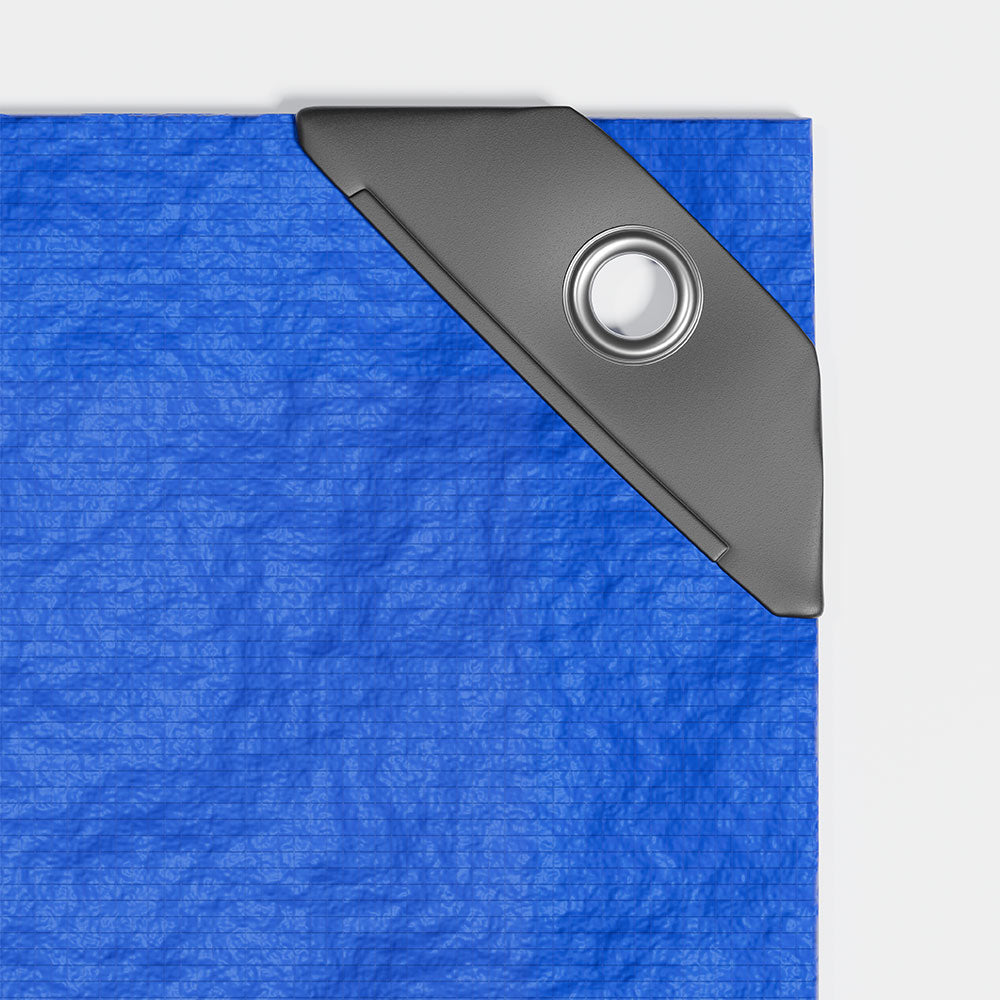

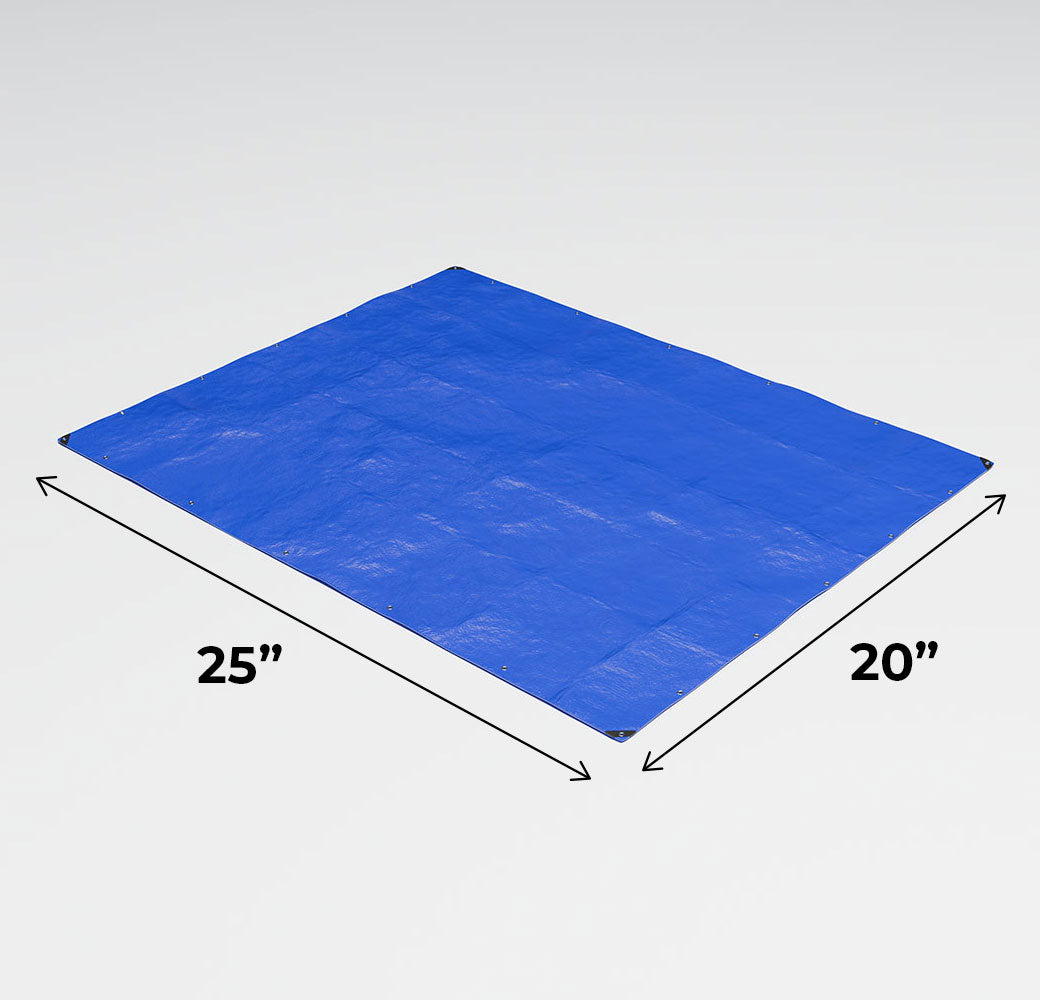

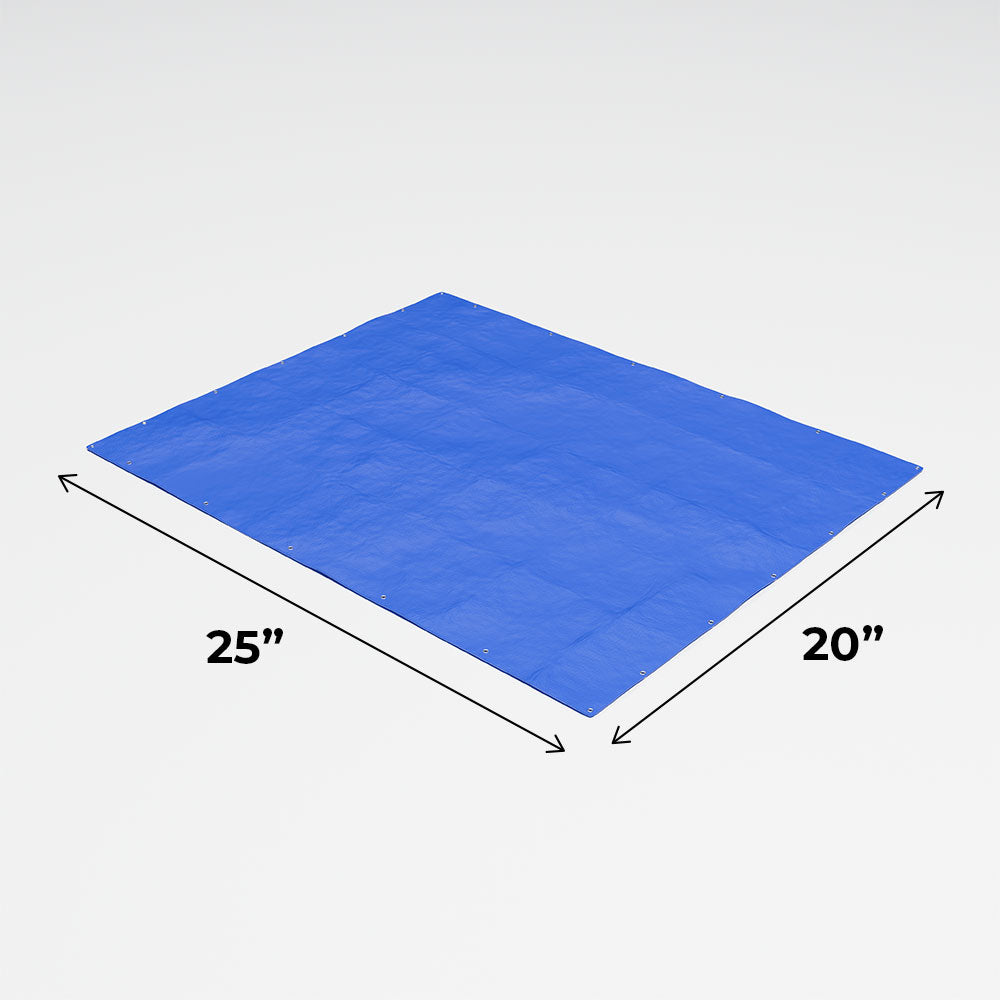

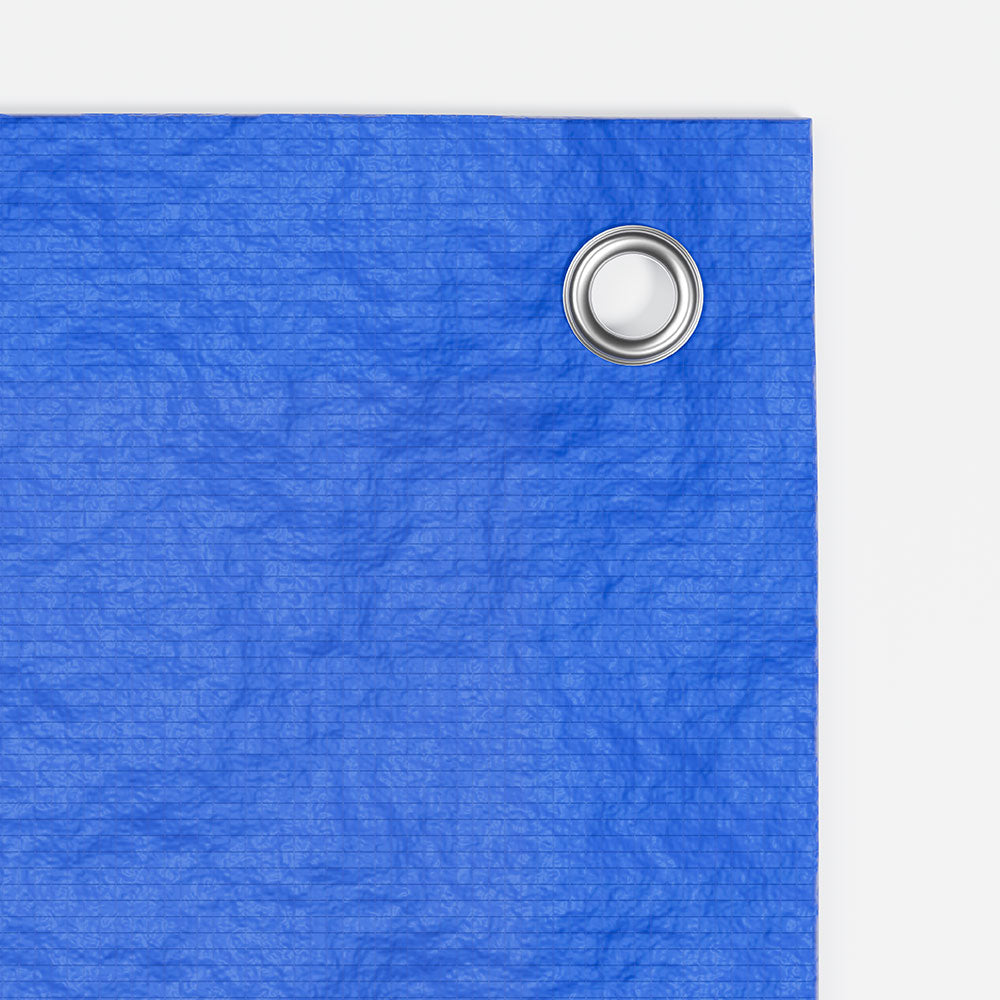

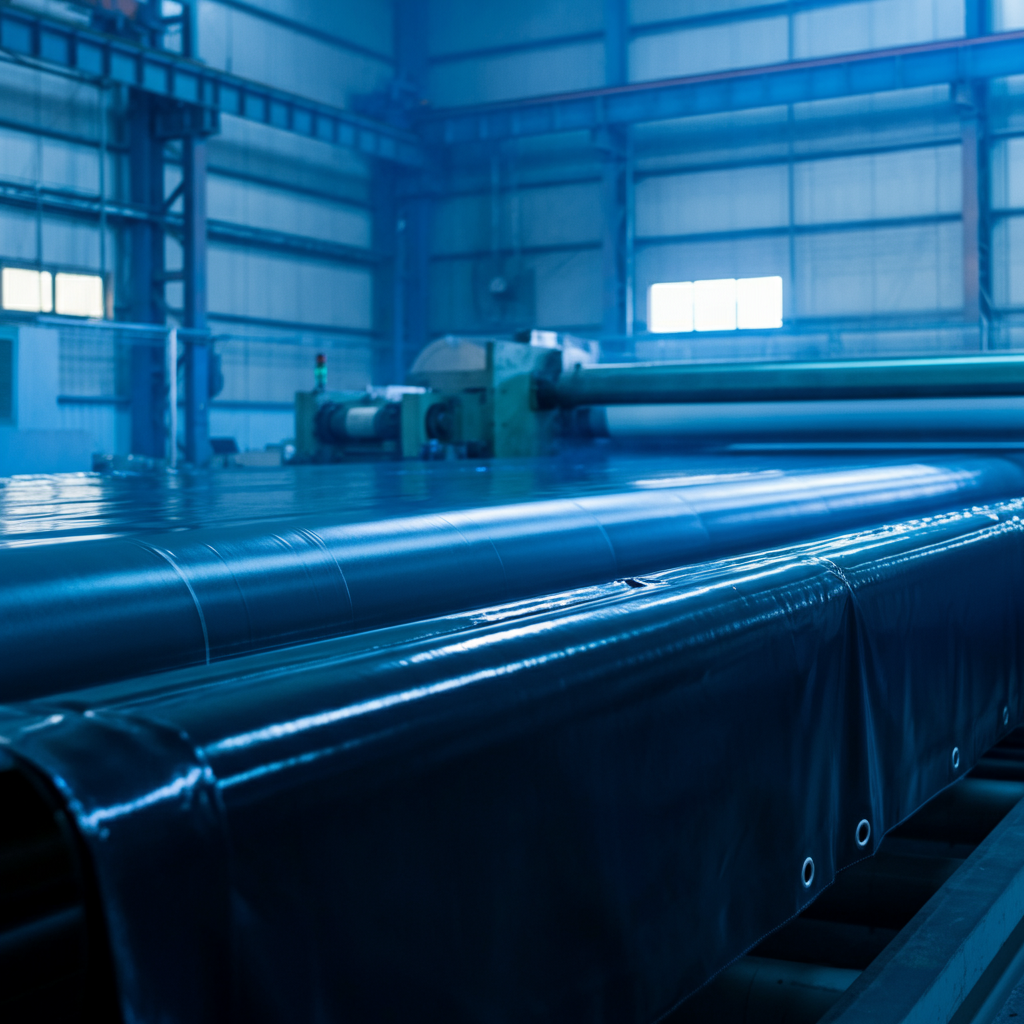

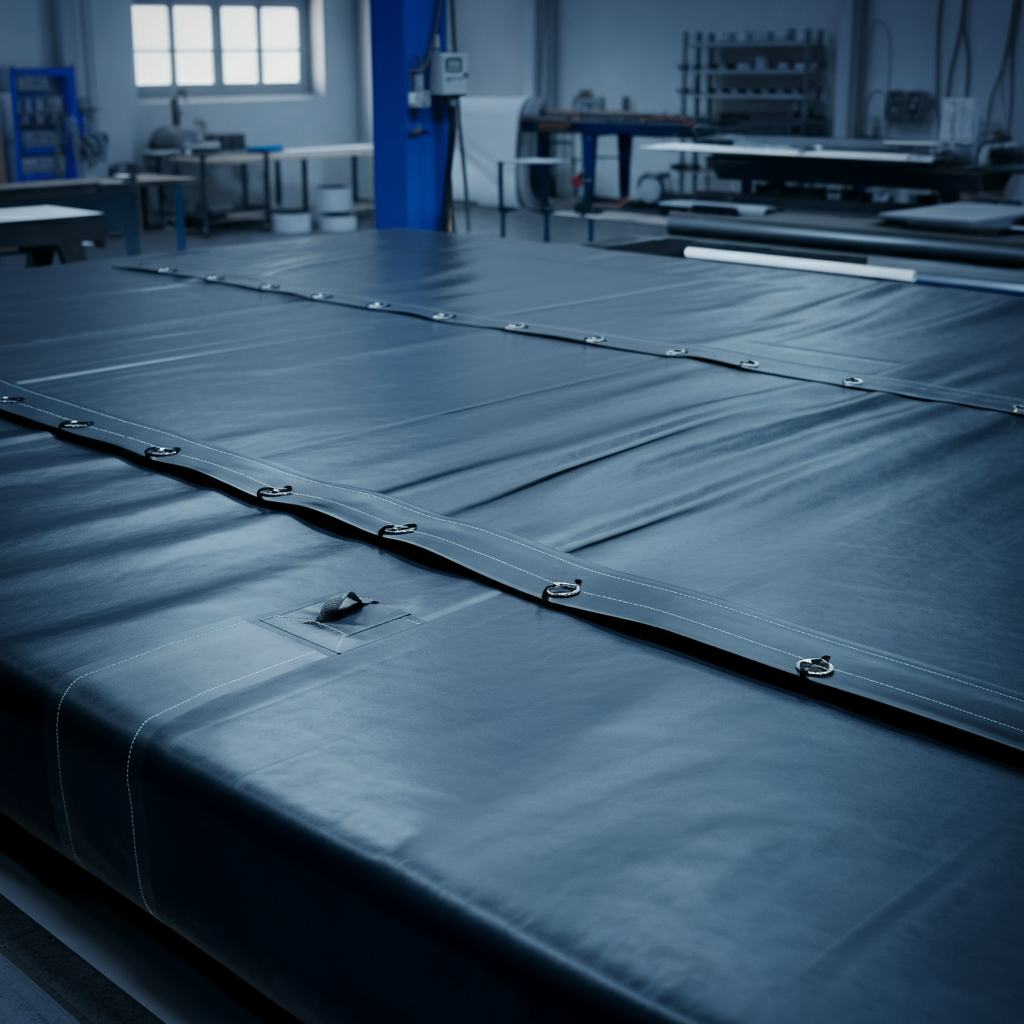

6. Cutting, Edge Sealing, and Reinforcement

What happens: Tarps are cut to spec dimensions, edges are folded and sealed to prevent fraying, and grommets are inserted at regular intervals for tie-down points. Corners may be reinforced depending on application.

DPALEX advantage: Every DPALEX tarp is sealed and reinforced to FEMA-spec or better. We go beyond simple hem folds by incorporating heat-seal or stitch-reinforced corners designed to withstand high winds and rough handling.

7. Kit Assembly (Para Cord & Packaging)

What happens: Finished tarps are folded, packaged, and kitted for distribution. For emergency response scenarios, the difference between a tarp and a tarp kit is critical as readiness depends on having everything needed for immediate deployment. Packaging must support long-term storage, quick distribution, and damage-free transport.

DPALEX advantage: Our kits include two (2) 100-foot lengths of 550 lb. test parachute cord, packaged with the tarp to eliminate delays in the field. Field teams don’t have time to source tie-downs on-site. DPALEX kits ship mission-ready, with rugged, military-grade cord for secure anchoring in storm, wind, or rooftop conditions.

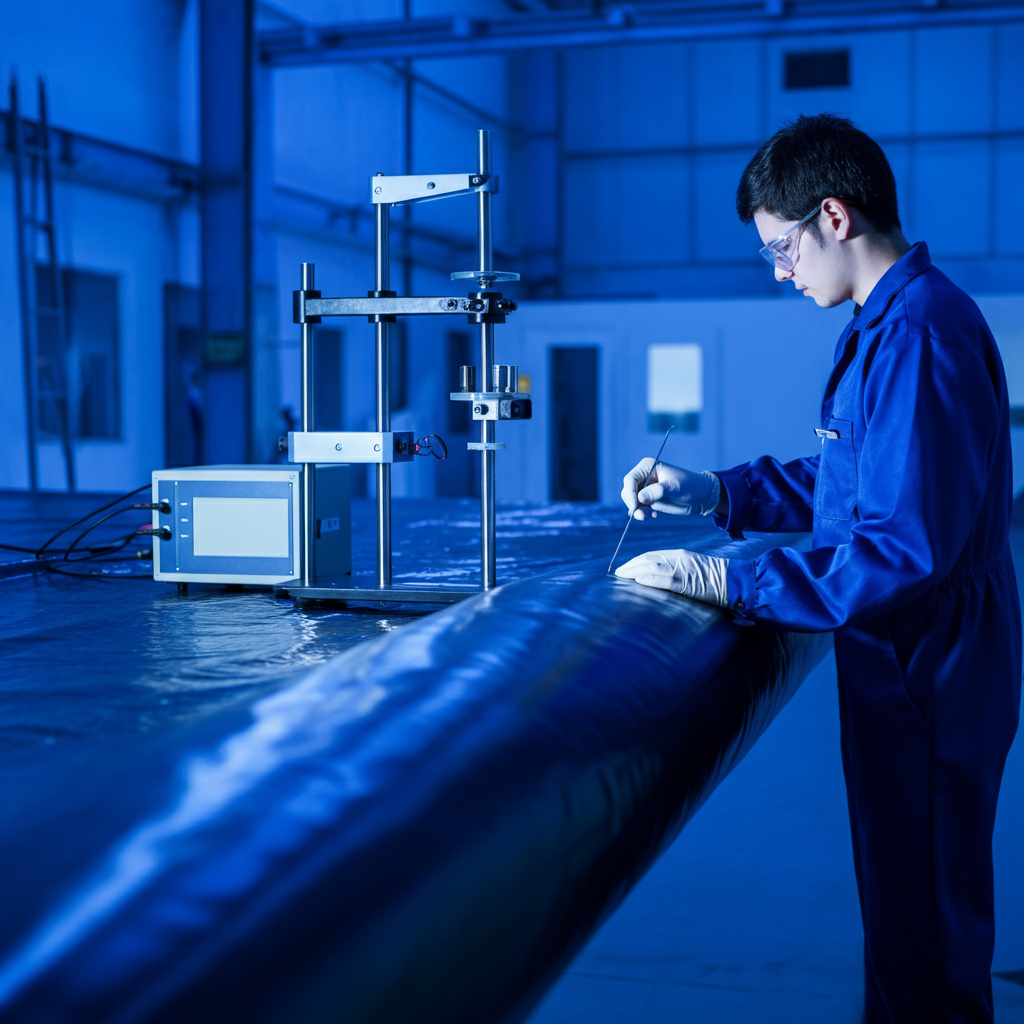

8. Quality Control & Certification

What happens: Final products are inspected and verified for consistency, durability, and compliance with key performance benchmarks. In many cases, competitors rely on outdated or one-time certifications that may no longer reflect the product being sold.

DPALEX advantage: Our tarps are independently lab-tested and certified during 2025 to meet NFPA 701, CPAI-84, ASTM E84, and ASTM D7238 standards. We don’t rely on old paperwork or unverified claims - our buyers get current, documented proof of performance.

Raising the Standard for Emergency Readiness

Conclusion. The difference is in the details. While others cut corners, DPALEX is built around readiness, reliability, and rapid response. Our tarps are not only tough, but they’re also tested, trusted, and tailored for real-world performance when it matters most.